Testing compressor without any instruments is perfectly possible by assessing FAD. A compressors capacity is generally determined by its Free Air Delivery (FAD) value which in turn determines the performance of the compressor.

What is Free Air Delivery ( FAD) of a compressor:

FAD (Free Air Delivery) is the actual quantity of compressed air converted back to the inlet conditions of the compressor. Design FAD will be generally stated on the nameplate of a compressor. This is the volume of air output an element or piston of a compressor delivers per minute.

Due to ageing and inefficiencies in internal components of a compressor this value deteriorates and hence capacity of an air compressor goes down. If a compressor rated at 1000 CFM is delivering an actual FAD of 800 then this indicates the capacity reduction. This, in turn, creates unnecessary power wastage too. Proper maintenance or minor spares replacement may bring back the design FAD easily in most of the cases. Hence periodic testing of FAD of an air compressor is important. In general FAD deviation with respect to design, should not be more than 10%.

This FAD value can be easily tested inhouse without any use of sophisticated instruments and this method is called a Pump UP method. This method is even prescribed by Bureau of Energy Efficiency.

Steps involved in Compressor Testing :

- Isolate the compressor along with its individual receiver being taken for the test from the main compressed air system by tightly closing the isolation valves. This ensures the full closing of the receiver outlet to the user end.

- Open the drain valve of the receiver completely and allow complete water in it to drain. Then reclose the valve to start the test.

- Ensure pressure gauge is available on the receiver and check for its accuracy. If it's not proper try to replace with new calibrated one.

- Start the compressor and note down the time taken for the pressure to rise from P1 to P2 through a stopwatch. For example, if the compressor is designed for 7 bar then you may take 1 bar as P1 and 6 bar as P2. This is user-determined and he has the freedom to take from any pressure range. Make sure it is wide to obtain accurate results.

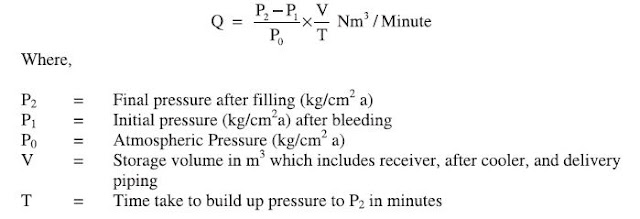

- Now Calculate the capacity or FAD of the compressor through below formula

- After compressor air gets heated up and this will have a direct effect on output volume. Hence to actually quantify the exact FAD of a compressor, rise in temperature need to be taken into account by multiplying the FAD value with the factor (273+t1) / (273+t2) where t1 is the ambient air temperature and t2 is the discharge air temperature.

Not just compressor but even the entire compressor system needs to be monitored and testing has to be done to identify the wastages happening. Leakage testing of a compressor is another important testing that has to be done very frequently to save huge amounts of energy.

Compressed Air Leakage Testing:

The leakage test has to be carried out when there are no compressed air users in operation. Run the compressor and pressurize the system to the normal pressure. Once the system reaches the normal operating pressure, the compressor will get unloaded.

If there are no leakages inside the plant, the compressor should remain in the unload condition and should not get loaded again. But, in actual practice, due to compressed air leakages, the system pressure will come down and the compressor will go to load mode.

The loading and unloading of the compressor indicate the compressed air leakage inside the plant. Note

down the load/unload time (take at least three readings).

The compressed air leakage can be estimated using the formula given below:

The system leakages = Load time x Compressor Capacity / (Load time + Unload time)

% leakage = Air leakage x 100 / Compressor capacity.

Conducting Leakage testing of compressor air systems has revealed that at 7 bar operating pressure and leakage orifice size of 3.1 mm will have around 3kW loss in energy.

Testing of the compressor has to be regularly conducted in the plant by the maintenance team to avoid unnecessary losses. As we know know that only 10% of the electrical input given to a compressor comes out as a useful output, a minute improvement in its performance also will have fantastic energy-saving benefits.

How you measure centrifugal compressor FAD?

ReplyDeleteSuch great information provided by you and your blog seems very informative. I am thankful to you for this. Thank you so much for sharing this article here. air compressor Canada

ReplyDeleteThank you your information which verified my formula so I am sure about it

ReplyDeleteThanks for sharing the best information and suggestions, If you are looking for the best SS 304 Valves, then visit Oshwin Overseas. Highly energetic blog, I’d love to find out some additional information.

ReplyDeleteI wanted to thank you for this great Information and knowledge, I definitely loved every little bit of it. I have you bookmarked your web site to check out the latest stuff you post. Your blog is eye-catching. I get pleasure from it. Thanks for sharing this beautiful piece of writing with me, get more information at Duplex Steel Flanges for more Great steel & metals related information and knowledge.

ReplyDeleteThis substance is essential and enlightening, which you have shared here about the Generator. Grateful for sharing this article here. Keep sharing your information reliably for my future reference. compressed air experts Ontario

ReplyDeleteAfter going through your contents I realize that this is the best of my knowledge as it provides the best information and suggestions. This is very helpful and share worthy. If you are looking for the best stainless steel needle valve manufacturers then visit Rache Process Equipment. Keep sharing more.

ReplyDeleteWhat’s up, every time I used to check blog posts here in the early hours in the break of day, for the reason that I enjoy to gain knowledge of more and more. Get more information at hastelloy tube manufacturers. As I am in fact eager of reading this web site’s post to be updated regularly. It includes nice stuff.

ReplyDeleteThe large air compressor was so boisterous it very well may be heard everywhere on the structure and down the square yet it controlled those three sanders from day break to sunset. Fortunately it paid for itself in saved sanding time rapidly. air compressor ohio

ReplyDeleteAs the P1 is the initial pressure after bleeding of receiver, would it be same as the atmospheric pressure P0

ReplyDeleteHi there to everybody, it’s my first go to see of this web site; this weblog consists of awesome and in fact good stuff for visitors. Hurrah, that’s what I was exploring for, what stuff! Existing here at this blog, thanks admin of this web site. You can also visit Stainless Steel Bolts for more Jignesh Steel related information and knowledge.

ReplyDeleteExtremely useful information which you have shared here about test and tag Melbourne for us .This is a great way to enhance knowledge for us, and also beneficial for us. Thank you for sharing an article like this.

ReplyDelete