Cooling towers are the most commonly ignored equipment in most industries. Its inefficient operation will have a considerable effect on the connected equipment. Out of various energy-saving opportunities in cooling towers, employing intelligent strategies in selecting the control parameter of the cooling tower operation will have a bigger impact without any considerable investment.

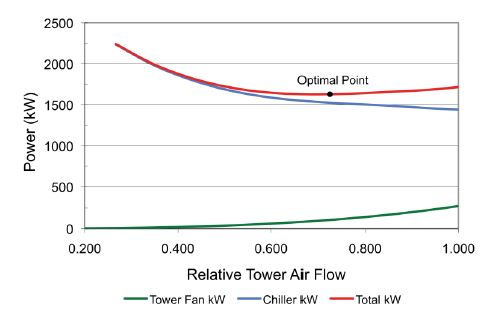

Cooling tower controls provide condenser water at the correct temperature to the chillers. Defining the correct water temperature is very important. Lowering the condenser supply water temperature increases the effort by the cooling tower resulting in more fan work, however, this improves the performance of the chiller by offering condenser relief (1). This chart shows how the power is affected by reduced tower airflow (higher ECWT) on the power requirement of an electric centrifugal chiller at full load.

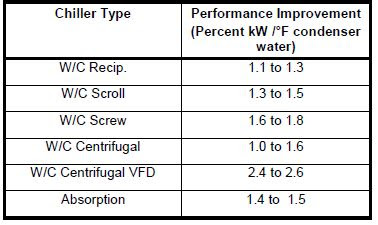

The below table shows the range of chiller improvement that can be expected by lowering the condenser water supply temperature. The best cooling tower control strategy is to find the balance point that provides the required cooling with the least use of power by the entire chiller plant.

Cooling Tower Temperature Control Method :

A method to control either a single cell or multiple cell cooling towers serving multiple chillers is to base the condenser supply water temperature on ambient wet-bulb. For this method, set the condenser water setpoint at the current ambient wet-bulb plus the design cooling tower approach (2) temperature. The set-point will change as the ambient wet bulb

changes as seen in the below figure. Limit the setpoint between the design condenser water temperature (typically 85°F) and the minimum condenser water temperature (typically 65°F). The wet-bulb method will provide good condenser relief for the chiller and cooling tower fan work relief when the chiller is not operating at 100% capacity. This can be a good balance between the chiller and cooling tower work.

Optimum Point Identification:

At a constant load and a constant wet-bulb temperature, the power consumption of both CT Fan and Chiller compressor varies with Condenser water temperature. And the interesting point to note down here is the optimum point won't be the lowest condenser water temperature always. Hence it requires a careful analysis of power consumption patterns for different wet-bulb temperatures. And then the optimum point has to be identified in each case and tower fan speed modulation has to be done accordingly. This is an effective closed-loop cooling tower control strategy. Below is a case where the variations of optimum point with wet bulb has been plotted.

Important Terms:

(1) Condenser Relief: Reduced temperatures at condenser side if provided the capacity of the condenser will enhance or in other words the load on condenser will decrease

(2) Cooling Tower Approach: This is the difference between cooling tower outlet temperature and ambient wet-bulb temperature. Cooling tower approach temperature is the minimum temperature a cooling tower can provide.

Source: Daikin Chiller Handbook

No comments:

Post a Comment