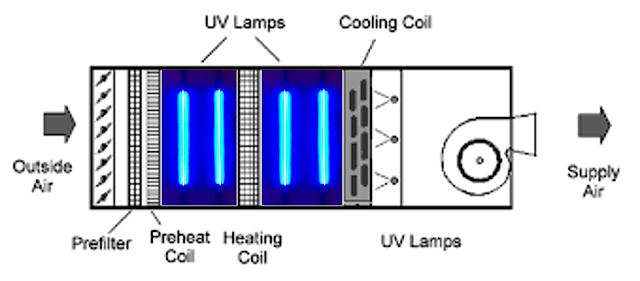

As Air-conditioning equipment starts ageing, its ability to maintain sufficient space temperatures and humidity levels drop. Most often, that’s due to the air-handling-unit (AHU) cooling coils’ decreased ability to remove heat from the air. Evidence shows this drop in performance, also known as coil-fouling, can occur within five years of startup due to the gradual buildup of contaminants on coil surfaces. This accumulation of material means the AHU’s coil is removing less heat and the fan is moving less air, and as a result, the space temperature and humidity are elevated. This may not be noticed by operators early on, but when it happens it’s often too late for coil cleaning. Then employing UV lamps on AHU units is found as a tantalizing idea.

Of course, there are energy and other cost penalties associated with coil fouling, when the facility engineer attempts to compensate for the reduced airflow and loss in heat transfer capability. Typically, the first step to compensate for this loss is to increase airflow, as advised usually by the engineer of record. The next is to reduce the temperature of chilled water entering the system, both of which are very costly to support from an energy standpoint.

It’s very important to note that even small changes in airflow and coil temperatures can dramatically impact cooling capacity. Therefore, both airflow levels and coil temperatures must remain at ‘as-built’ conditions for a system to use only that amount of energy, as when new. The most cost-effective way to ensure this is through surface irradiation by a UV-C lighting system, according to ASHRAE.

UV Lamps - C Range ( Short Range)

UV-C is ultraviolet radiation with wavelengths in the range of 200 to 280 nm, considered as the best wavelength for germicidal control and for disinfection systems. This radiation disrupts the DNA of a wide range of microorganisms rendering them harmless. The benefits of UV-C surface irradiation systems include maintaining indoor air quality and comfort levels with “minimal wasted energy” along with reliable disinfection caused by different types of germs. For new systems, UV-C maintains ‘as-built’ conditions from the very beginning. For retrofit applications, UV-C removes organic accumulation and growth on coil surfaces on both the outer and inner surfaces, and similarly, it cleans drain pans and other interior surfaces. Shortly following the UV-C application, the surfaces stay clean to maintain original specification conditions thereafter, as long as the lights are maintained.

Performance losses from contaminant buildup have led many building operators to retrofit their air-conditioning systems with UV-C light systems after coil cleaning attempts have failed. UV-C technology can reduce mold and biofilm, coil pressure drop, and coil-cleaning needs. ASHRAE also recommends UV-C irradiance levels, which are specifically followed in all UVR sizing methodologies whether automated or manual.

Types:

Cylindrical UV lamps may be any length or diameter. Like fluorescent lamps, most UV lamps have electrical connectors at both ends, but single-ended versions also exist. Typical diameters are 1.5 in. T12, 1.1 in. T8, 0.79 in. T6, and 0.63 in. T5

Biaxial UV lamps are essentially two cylindrical lamps that are interconnected at the outer end. These lamps have an electrical connector at only one end.

U-tube UV lamps are similar to biaxial lamps having the electrical connector at one end. They have a continuously curved bend at the outer end.

UV lamps can be grouped into the following three output types:

Standard-output UV lamps operate typically at 425 mA.

High-output UV lamps have hot cathode filaments sized to operate from 800 up to 1200 mA. Gas mixture and pressure are optimized to deliver a much higher UV-C output while maintaining long lamp life, in the same lamp dimensions as standard-output lamps.

Amalgam UV lamps have hot cathode filaments sized to operate at 1200 mA or higher. The gas mixture, pressure, and sometimes lamp diameter have been optimized for delivering even higher UV output without deteriorating lamp life.

UV Lamps Cost Details

UV lamps are easy to size and install in ventilation systems. Many users reported around INR 8 - 10 per CFM for a typical high energy UV lamp systems. The cost of operation of these UV Lamps in ventilation systems consumes around 1 % of the total system energy. The initial capital cost of UV Lamps is almost equal to that of one-time deep coil cleaning charges and associated costs for system downtime. As a result, it might be more rational to make a one-time investment in a UV-C system that will keep cooling coils at as-built conditions… to cut energy waste and maximize comfort in most any occupied space.

Hazards of UV Lamp Radiation to Humans

UV-C is a low-penetrating form of UV compared to UV-A or UV-B. Measurements of human tissue show that 4 to 7% of UV-C (along with a wide range of wavelengths, 250 to 400 nm) is reflected and absorbed in the first 2 micrometers of the stratum cornea (outer dead layer of human skin), thus minimizing the amount of UV-C transmitted through the epidermis

Although UV is more energetic than the visible portion of the electromagnetic spectrum, UV is invisible to humans. Therefore, exposure to ultraviolet energy may result in ocular damage, which may initially go unnoticed. Ocular damage generally begins with photokeratitis (inflammation of the cornea), but can also result in inflammation of the conjunctiva (ocular lining). Symptoms, which may not be evident until several hours after exposure, may include an abrupt sensation of sand in the eyes, tearing, and eye pain,

UV-C energy does not normally penetrate through solid substances and is attenuated by most materials. like Quartz glass, soda barium glass, and PTFE plastic that have high transmissions for UV-C radiation. Energy from UV lamps can reflect from most polished metals and several types of painted and nonpainted surfaces; however, a surface’s ability to reflect visible light cannot be used to indicate its UV-C reflectance. The fact that a blue glow can be observed on the metal surface from an operating low-pressure UV fixture lamp could indicate the presence of UV, and measurement should be performed to ensure there is no exposure risk. The lack of reflected blue light does not necessarily indicate the absence of UV energy.

Well-designed and commissioned UV-C installations, education of maintenance personnel, signage, and safety switches can avoid overexposure. During commissioning and before operation of the UV-C installation, hand-held radiometers with sensors tuned to the read the specific 254 nm wavelength should be used to measure stray UV-C energy (primarily in upper-air systems).

Excellent post. I really enjoy reading and also appreciate your work. This concept is a good way to enhance knowledge about Heating and Cooling Toledo. Keep sharing this kind of article, Thank you.

ReplyDelete