INTERMETALLIC COMPOUND BASED ACTIVE REFRIGERANT

AGENTS FOR CHILLERS

Overview

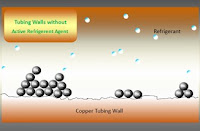

Most of the vapour compression air conditioning and

refrigeration systems have a mechanical compressor which relies upon

lubricating oil to function. During the normal course of the refrigeration

process, 0.5 % to 8% of the compressor’s lubricating oil is circulated

throughout the system along with the refrigerant. This compressor oil gets builds

up on the metallic walls of the refrigeration tubing reducing the heat transfer

from the refrigerant to the walls of the refrigerant tubing.This phenomenon is

called oil fouling.

This oil fouling of the heat transfer surfaces of air

conditioning system will cause a loss of efficiency. This loss is about 7%

after the first year, another 5% after the second year, and a further 2% per

year the following years.

This loss will continue to accumulate until equilibrium is achieved between flow force and adhesion (surface tension). At this point the oil boundary layer formed has achieved its maximum thickness, producing maximum loss of efficiency. Usually, the efficiency degradation will peak somewhere between 20% and 30%. Published information by ASHRAE confirms these observations: performance is degraded by as much as 30% due to the build-up of lubricants on internal surfaces .Higher percentages up to 40% have been observed in systems 20 years old or older.

This loss will continue to accumulate until equilibrium is achieved between flow force and adhesion (surface tension). At this point the oil boundary layer formed has achieved its maximum thickness, producing maximum loss of efficiency. Usually, the efficiency degradation will peak somewhere between 20% and 30%. Published information by ASHRAE confirms these observations: performance is degraded by as much as 30% due to the build-up of lubricants on internal surfaces .Higher percentages up to 40% have been observed in systems 20 years old or older.

Active refrigerant agents are those compounds available in

the market through which the above said loss due to thermal fouling can be

resolved through their properties.

Working

Active refrigerant agent is an intermetallic compound

technology which, when introduced into the refrigerant oil of a refrigeration system,

forms a permanent bond to metal surfaces. This action removes oil fouling,

changes the thermal nature of the metal and lowers the boiling point of the

refrigerant gas, resulting in a more efficient operating system with

substantial energy cost savings.

The polarized molecules of active refrigerant agent

will create a new film essentially one molecular in thickness on the inner side

of the coils.This restores the ability of the system to transfer the heat load efficiently.

More efficient heat transfer results in lower head pressure and less work

required by the compressor. More efficient heat transfer also results in colder

evaporator coils, which allows for the set point to be reached quicker. This

can allow the compressor to cycle off more often, thereby running less reducing

electrical operating costs.

|

Case

Study:

An IT

facility in Hyderabad went for Active refrigerant agent addition in their

200 TR chiller and have achieved a reduction of 5 units per hour of operation.Facility has achieved nearly 16% energy savings.

|

No comments:

Post a Comment